Anet A8 Tatara steel frame by Orballo printing - REVIEW

After my first steps in hobby 3d printing with Anet A8 it was time to make some serious upgrades. Was never too interested in aluminum AM8 version after I saw Tatara steel designs (v1, v1.1). Since shipping from USA to Europe is not cheap, I started searching for European suppliers. It was not as easy as I’ve hoped.

I found some on Ebay UK for 77 GBP + 23 GBP shipping. Totalling to 116 EUR. Local cutters quoted it 200 EUR (!). Both options also leave you with raw steel surface which needs further work (polish and/or color). Then Orballo printing website popped out and it offered their own version for 71 EUR + 15 EUR shipping and is in black powder coated!

But let’s go from the beginning…

- Orballo printing service impressions

- Orballo’s Tatara steel frame derivative for Anet A8 - first impressions

- Assembly

- First tests and impressions

- “Before and after” prints

- So, how good is Orballo Printing Tatara steel frame for Anet A8?

- All together… from website to print - the verdict

- TODO

Orballo printing service impressions

This company (Spain) was not very well known so I decided to check it online. TrustPilot had more than a few very bad reviews on their service! However it got as much 5-star ratings too. Still, I was worried. While I was browsing the website, Hugo from Orballo contacted me through their website chat. That already was not in line with some reviews about non-existing support, but hey, maybe they invest time in pre-sales and not after sales. Hugo tried to explain that they had only a few issues but that they were all resolved, that they were swamped with work during that time, but still… it took me more than a month to come back and order it.

Website:

Nice design, practical and user friendly. However, it is rather slow. Some parts are not translated too. What I also don’t like is that prices are “tax excluded” at first. After you log in, prices change to “tax included”. Since I logged in as a company with EU VAT ID, I would expect it the other way around. I would also expect payment for EU resident companies to exclude VAT but that was not the case by default. However, I didn’t want to bother with that so I just ordered without raising the ticket.

All in all I give it 4/5, partially also because of the reasons products are not described as detailed as I would like (read below).

Packaging and delivery:

27-2-2019 (Wednesday) - I ordered and payed (late afternoon)

28-2-2019 (Thursday) - Order status was “in progress”

1-3-2019 (Friday) - order was in “shipped” status

… at that time I wanted to change my order (wanted black screws set instead of regular ones). I contacted Hugo and he replied fast that he will take a look but he believes it will be possible. Maybe this was the reason why same day order went to “labeled” status.

4-3-2019 (Monday) - order is in “shipped” status again

8-3-2019 (Friday) - I received the package (Croatia)

Orballo’s website claims 24h for shipping. I cannot confirm exact time 100% because I changed my order during this process, however it was not 24 hours for sure. On the other hand, it does seem fast enough. Although, at the end I didn’t receive black screws but regular ones so I wonder why the delay. I didn’t get any message on the status of that order.

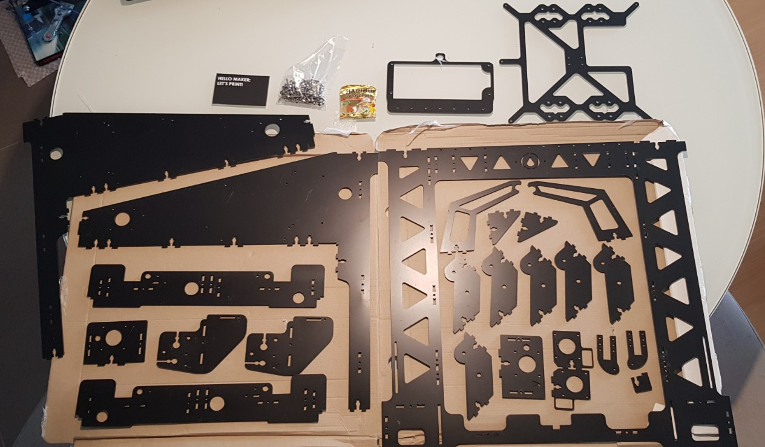

Package arrived in thin cardboard box and individual pieces wrapped in thin foam sheets. I’d say it is OK. Some styrofoam would be better but I nothing was damaged in transport.

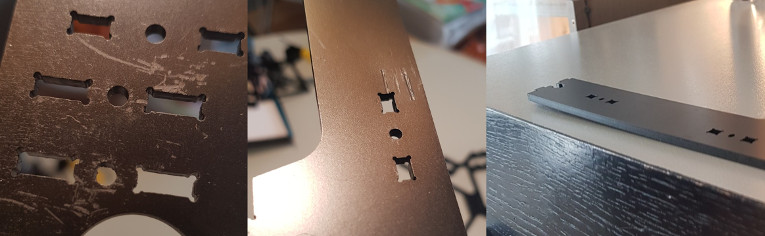

However, there were some scratches on the surface and some very minor bending. Some worse case examples you can see on the photos. Scratches don’t look like they were made in transport. It’s more like frame (or part of it) was assembled before. Or it was just not handled too carefully in production process. Personally, I don’t care. It’s steel frame, not underwear :D

Anyway, all together, it is 4/5.

Orballo’s Tatara steel frame derivative for Anet A8 - first impressions

First impression after unpacking everything was very positive. Small pack of Haribo candy was a nice touch. Something to chew on while assembling :) I also see Y belt tensioner metal parts are included, but also spool holder parts, nice. Only one minor error in production found but without any visual or functional effect. Closer inspection reveals that not all plates are exactly 3 mm thick. It varies from 2,80 to 3,00 mm. It might be polishing before powdering, or sheet tolerance, not sure. I don’t feel like it has much influence on stability of the frame.

There’s also no assembly manual but who needs one right? I don’t see how people replacing frames of their DIY 3d printers are not also able to do it without manual. Also, there is enough Tatara stuff online and it should be the same.

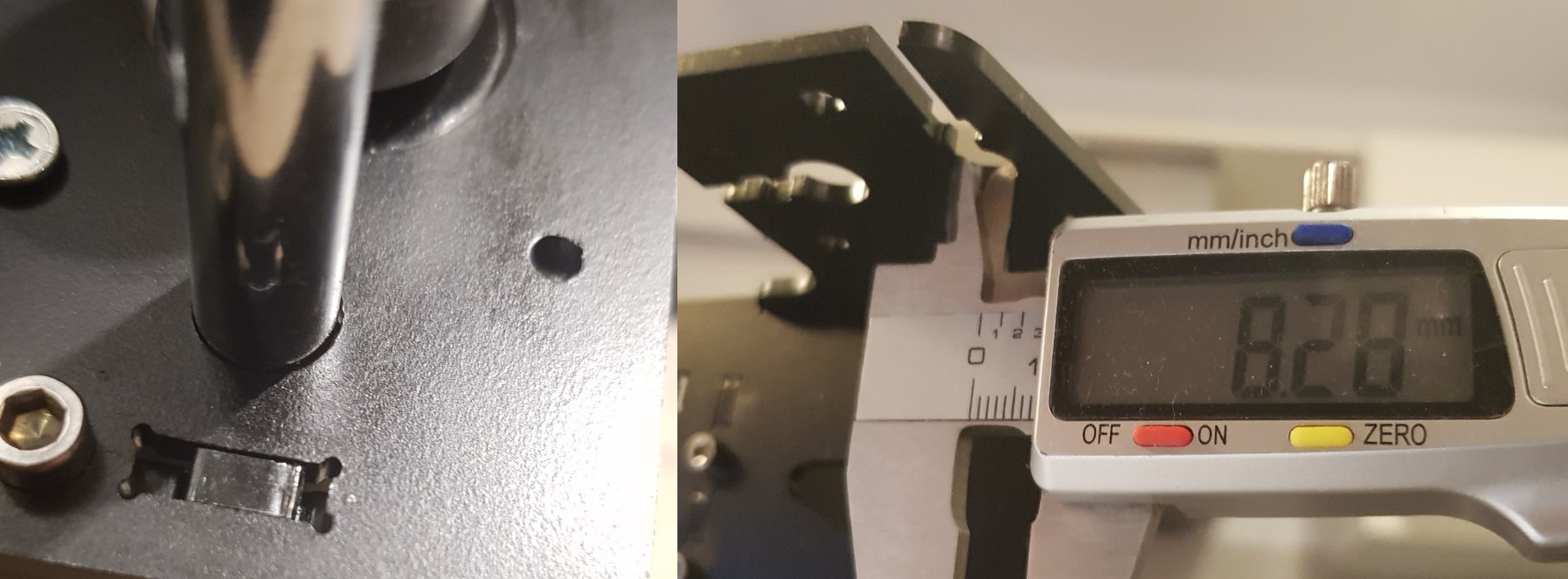

When I was asking a local cutter for a quote on cutting Tatara frame, I remember very well that tolerance on steel rod holes was H7. That is -0/+0.018 mm in diameter. This ensures tight fit of steel rods and no wobble. Tatara team suggests other methods of fixing steel rods if that tolerance cannot be met. And here comes my first real worry about Orballo’s Tatara frame, holes were 8,28 mm! I’m afraid steel rods will wobble. We will see.

Further comparing with original Tatara specs just made things worse, but this time I was to blame. Somehow, I expected Orballo is too small company to do much custom designing. When reading “Tatara derivative” I expected they changed a logo on it only. Oh I was wrong. Main frame is much narrower, left and right side for about 15mm, top one too. This however may also be an advantage. This way, there is more space left of the bed to squeeze in bed cable chain. Some steel frames make it hard to do.

It’s still massive and made of steel and I cannot believe that makes much of a difference in rigidity but then I noticed bottom part was changed even more. Orballo removed rigid square frames below the bed, that extend outside and also provide a place to screw in rubber feet to avoid vibrations. Instead, they used much less rigid corner brackets. Knowing one of the biggest flaws of original Anet A8 frame was bending of front Y axes plate, I really disliked this solution. Also, those brackets do have some holes in them, that appear to be useful for screwing in rubber feet, but they’re located too much inside, 10cm away from outside boundaries of the printer and it doesn’t leave me much confidence in stability.

* (Original tatara on the left. Images taken from Orballo and Tatara pages)

More on exact changes from original Tatara frame later. For now, I can just stay that initial good impression turned to worry.

Assembly

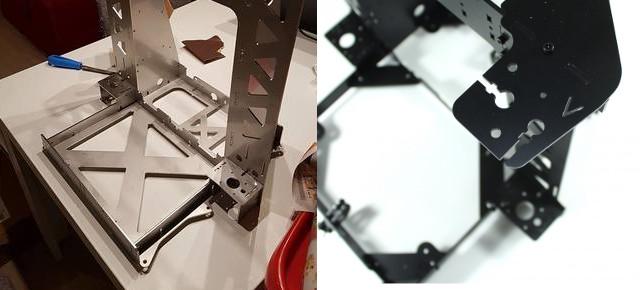

It starts great, easy. No manual needed if you have seen a single photo of any similar frame. Holes fit perfectly and securely, and everything is tight and square. I managed to level top and bottom (front/back) plates to only +/- 0.01 degrees difference. Obviously, fact that some parts were a bit bent had no influence on rigidity of the frame.

After first 5 main pieces of the frame are assembled, small issues arise. First, this is marketed as “drop in replacement” but it is not 100% true. Because original Anet A8 frame is 8mm thick and this frame is 3mm, original screws are too long. I anticipated this earlier, thanks to Orballo’s website which offered “related products” on their website when I was ordering the frame. It suggested Prusa i3 frame M3x12 screws package so I ordered that too for about 4€ extra. I’m sorry that only suggestion was regular metallic color and they also offer black ones. I discovered it manually too late to change order. New screws are also way better and they look better. It’s really not an option here, simply buy those too. I think it would be better if Orballo included it in the package with the frame actually. 4€ lower price cannot measure up with frustration of the clients when they try to use the old screws on this frame.

More issues with screws appear. I don’t know how their steel Prusa i3 frame is, but those do not fit Anet frame completely. In example, I cannot screw down X axis motors. Plate is now 5mm thinner and holes in my steppers (original) are not that deep. I found some ugly ones around until I buy new ones. Similar thing, but only visually, is with LCD screen holder. You can screw it with those 12mm screws but 10mm ones would not stick out. Same happened to several less important places like PSU, electronics, etc. Nothing important but for visual puritans, it can be better.

I must say that Tatara team left a big impression on me. They gained my trust with high quality design, rigidity measurements and other material that really explains and supports their design choices. Then they gave it away to Open Source and refuse to even earn money on selling cut frames. You ran into those small design details all the time. In example, Z axis motor plates. Tabs and holes are made in such a way that you can assemble them *after* you have already tightened main frame parts. Tabs are a bit narrower and holes wider, which enables you to slide parts in with no effort. On the other side, small things like that just confirm my suspicion how Orballo is not on that level. Bottom plates I mentioned earlier they replaced with some sort of corner brackets. Of course, those brackets do not have tabs so carefully designed and cannot be inserted later. I had to unscrew front and back plates to insert them. It appears I was wrong about assembly manual. You will be able to assemble frame without it, but you will have some setbacks and you have nowhere to look as this is not a original Tatara frame. Some frustration piles up slowly.

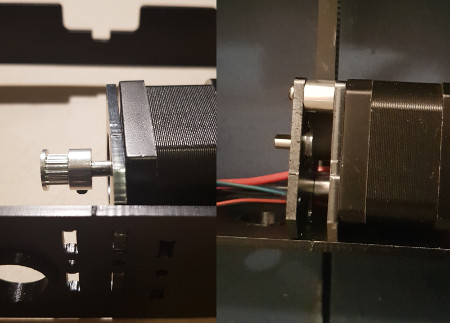

Next setback is Y axis motor plates. There are 2 identical plates here, similar to only single plate of original Tatara v1 (Tatara v1.1 changed the design here completely). And there are 3 assembly holes in the plate. Hm. Original Tatara suggests a single plate in the rightmost hole but supplied plates do not fit. If you use single plate in the middle hole, pinion is not centered with the belt. Only after watching Orballo i3 Prusa video I realized both plates go in 2 (left) holes, pinion is flipped and 9mm spacers are put between plates (not to mention that supplied screws don’t fit anymore because of this). Actually I like this approach more than Tatara’s. It’s way more rigid. Tatara also detected this and upgraded design for v1.1 but this works great too. However, you need longer screws, you need 9 mm spacers. You can print spacers (here) but probably your printer is disassembled by now! I did research of what I need to print before, but there was no way I could have known about this. Luckily, I had some 9 mm aluminum spacer laying around from my CNC project.

* (left: how I thought it should be, right: how it should be + some spacers I’m missing. And yes, supplied screws are too short here)

If you don’t want to do that mistake yourself, here is the list of what you need to get printer in workable state and to avoid future disassembly:

- Y axis motor spacer

- Tatara for ANet A8 printable parts - what you need from here is Y axis belt tensioner, 2 x Belt Y bed fix, Belt Y bed fix top

- not necessary but to avoid ruining your cables I suggest printing some square and round cable helpers from the link above

That said, what didn’t seem like a problem at the start slowly piles up frustration. It’s ok not to include manual but then stick to original Tatara design or include all the necessary parts and screws. This product just cries for correct screws and printable parts set (later ones at least in digital form).

Another difference in design… Z axis stop switch is fixed to the frame using only one slot while original Anet and Tatara use two. Not a big deal since this is a steel frame so you can tighten the screw without worrying about plastic breaking. But still, I really don’t see why effort was taken to make things worse.

Bed is exact copy of Tatara v1.1 (improved v1 version, tiny bit less rigid but 100 g lighter). Good. I used the opportunity to replace the Y axis belt with a better one (with fiberglass). Y axis bearings I replaced with IGUS ones long time ago.

Electronics fit perfectly, holes are correct. LCD screen needs some more printed parts but it is good enough to test. All in all, not the best experience but it ends up with rock solid frame. It does not bend, sits on the flat surface perfectly with no movement at all. Only two things worry me at this stage: steel rods wobble because of too wide holes and front Y axis plate bending because of redesigned bottom frames. But we will see about this in print tests.

Assembly: 3.5/5

First tests and impressions

Very first impression after switching it on and leveling the bed was that printer is more quiet! It seems original Anet frame added to some noise and I wasn’t really expecting it. There is no visible movement of the frame while printing. It is much easier to (re)level bed now because with original frame, every movement of the printer, ever the slight one, made a big difference. Not anymore.

About Y axis front plate bending… until I tightened the belt I could move it about 0.5mm with my finger (compared to maybe 2 to 3 mm on the original Anet frame). It was still too much. However, after tightening the belt, this is not visible to a naked eye anymore. However, I still hate this and prefer original tatara design.

About steel rods wobbling: fixing bed and tightening the belt, also fixing Y axis decreased a wobble but it is still there. Some force is needed to make them move and I wonder if that amount of force is going to be reached when printing but I don’t like it. It’s just a matter of drilling 8 mm holes with better tolerance. I shouldn’t need to deal with this.

May old Anet frame was skewed. I haven’t calibrated the printer yet but I had to delete skew compensation in Marlin. It appears to be perfect or only very slightly skewed.

My LCD screen started to show garbage during print. It is static interference. Is it a metal frame or I wired LCD screen cable closer to other cables this time? You can find many solutions to this online, but I just wrapped some aluminum foil around it and it seems to works now.

At this point, I replaced only the frame and Y axis belt. IGUS bearings on the bed were already there and everything else the same. I don’t have many old test prints but found 2 simple ones to make the comparison. Let’s see how those compare.

“Before and after” prints

The main “enemy” of my old Anet frame was vibration, both on X and Y axes. I managed to make some almost perfect prints after carefully tightening belts, re-leveling bed, slowing down the speed, but it wouldn’t last long before ringing effect was visible. That was what I wanted to eliminate with this upgrade. Second goal for me was to increase the speed. Tatara frame should be able to take double acceleration and jerk.

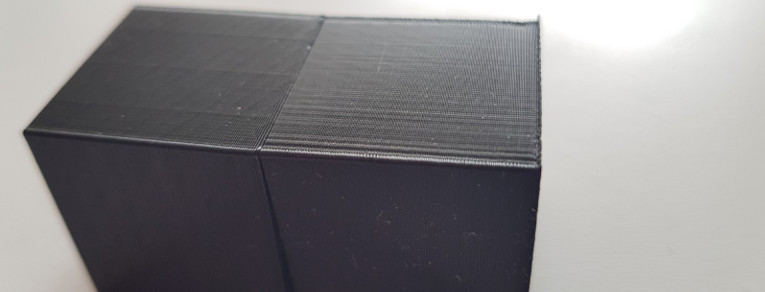

Test 1 - 20mm hollow cube

Speed 50mm/s (walls 25mm/s), 0.2 mm layer hight, 0.45 mm layer width, 0,4 mm nozzle, 205 C extrusion (Devil Design PLA)

Very simple test of flat surfaces but also the one that shows effects of vibrations. On the right side is old Anet print. At the bottom edge you can see lines caused by vibration. As I said, I could make them go away for short period of time but they would always come back.

On the left side you can see a new print. Those lines are completely gone. For now, ignore diagonal lines on the new print. This is a problem unrelated to the frame (I’m suspecting the fan).

Test 2 - Marvin figure

Speed 50mm/s (walls 25mm/s), 0.2 mm layer hight, 0.45 mm layer width, 0,4 mm nozzle, 205 C extrusion (Devil Design PLA)

I printed maybe 50 Marvins on the old Anet with variable success. However, ringing behind his ears was present on each and every one of them. You can see it on the right. On the left, was my first try and it is not visible anymore. Again, ignore other flaws on the print, this test was targeted at ghosting/vibration and printer/filament is not calibrated well yet.

So, how good is Orballo Printing Tatara steel frame for Anet A8?

Obviously, this is not a complete test. Still much to do (read on to TODO section). But it is enough to form some opinion of the product and Orballo service. After some printing I’d give 4/5 for quality of assembled frame. This wobble in smooth rods worry me, I don’t like Orballo’s bottom frame compared to Tatara (no rubber feet and front plate not so rigid). In fact I already started designing upgrades to address some of those issues (Z axis anti wobble). We will see how it goes and I’ll report.

But point is, I didn’t want to deal with this. I wanted the best metal frame I can find. Tatara guys left an impression on me. It is a very professional and well thought product. But then comes Orballo’s “derivate” which I don’t understand. Don’t get me wrong, I have positive opinion about Orballo printing, I can definitely see some time and effort invested in their business. They design and sell their own custom full steel Prusa i3 printers, they have good prices and good service. Somebody there had to sit down and spend hours in CAD to change Tatara designs, test them, manufacture and sell. What I don’t understand is WHY? I don’t see any improvements (except maybe Y axis motor plate) so my only conclusion is that they wanted to cut down on costs. But then they include spool holder and black powdered finish which definitely is not cutting down costs. Was it worth 30€ (+ painting) difference for me or I was better off ordering original design from Ebay? Honestly I don’t know. I can tell it’s not the best frame out there, at least not in Europe. Best value for price? Most probably.

All together… from website to print - the verdict

I already wrote about Orballo service and after assembling the printer I think I need to come back to that. I like the company, their prices, website, selection of products, communication with Hugo. I will buy from them again. I also see some effort there to make their own products and to make them good and affordable. However I cannot shake off the feeling they’re just one step too short. Maybe understaffed? Sometimes I have a feeling it is a single person company. Just a few tiny steps are required… include manual or video, include correct screws with the frame, link to printable parts, take more care in documenting your in-house products online. If you have to change excellent Tatara design, explain why! Explain what were your goals and compromises made, backup your decisions with facts and comparisons, stand behind it! Right now, I have many Tatara posts, user group, tests and documents where they explain their choices and stand behind it. Orballo has almost nothing to back up their design changes and then only authority of designer is waged. Tatara wins there easily.

Pros:

- relatively fast delivery

- good communication with seller

- huge improvement compared to original Anet A8 frame

- black finish and spool holder included

- good price

Cons:

- no manual (and you do need it!)

- not as rigid as original Tatara design (main frame narrower, bottom frame dramatically changed, no proper place for rubber feet)

- smooth rod holes wobble as are not made to Tatara tolerances (holes too wide)

- screws set is extra and does not 100% fit this model

Verdict:

Recommend? YES

Final rating: 4/5

TODO

I’ll update this post and (hopefully) write new ones as I manage to do more tests and upgrades. On my list is:

- properly calibrate printer and do more complex tests (speed tests too!)

- design and upgrade parts to fix wobbly smooth rods

- test if fixing leadscrews is a good thing to do or makes things worse

- upgrade to Titan extruder (Bowden) with V6 hotend and BL touch sensor (all AliExpress copies)

- upgrade board to RAMPS 1.4 + MEGA2560 + LCD 12864

- upgrade to Octoprint using Raspberry Pi B

- make alu extrusion/wood/plexiglass enclosure with smoke detector, external display and camera

So… stay tuned for news and please comment/correct me if I made any errors!

Leave a Comment